Golden Lion Grrrages

Golden Lion Grrrages 1960 Chrysler 300F

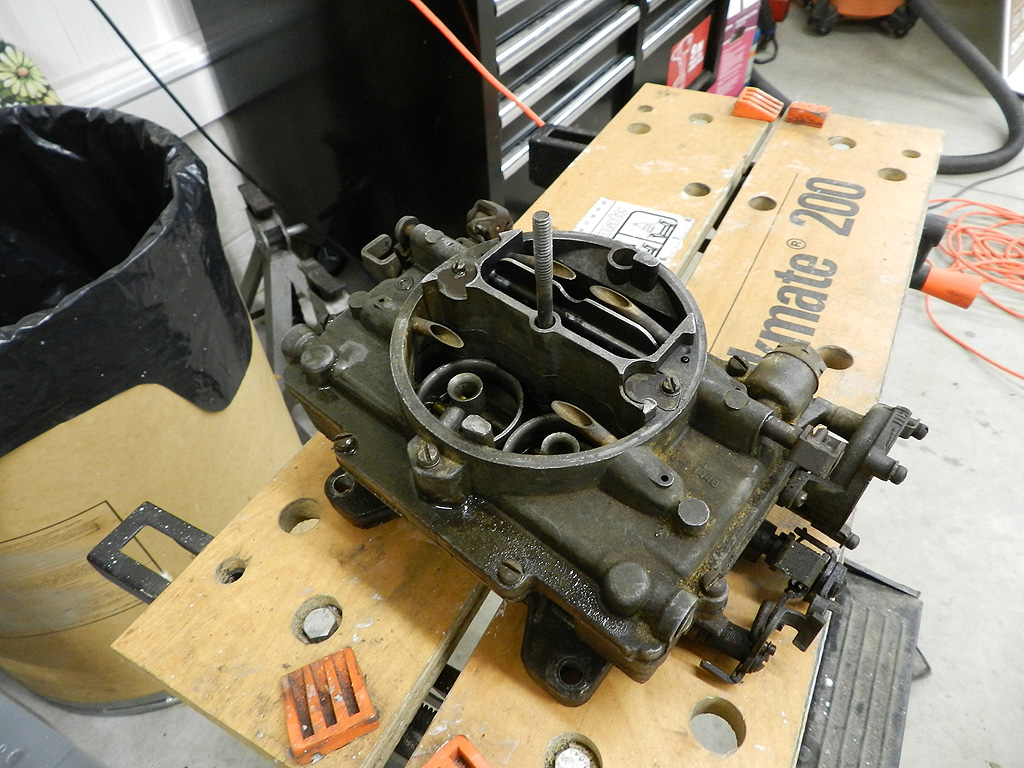

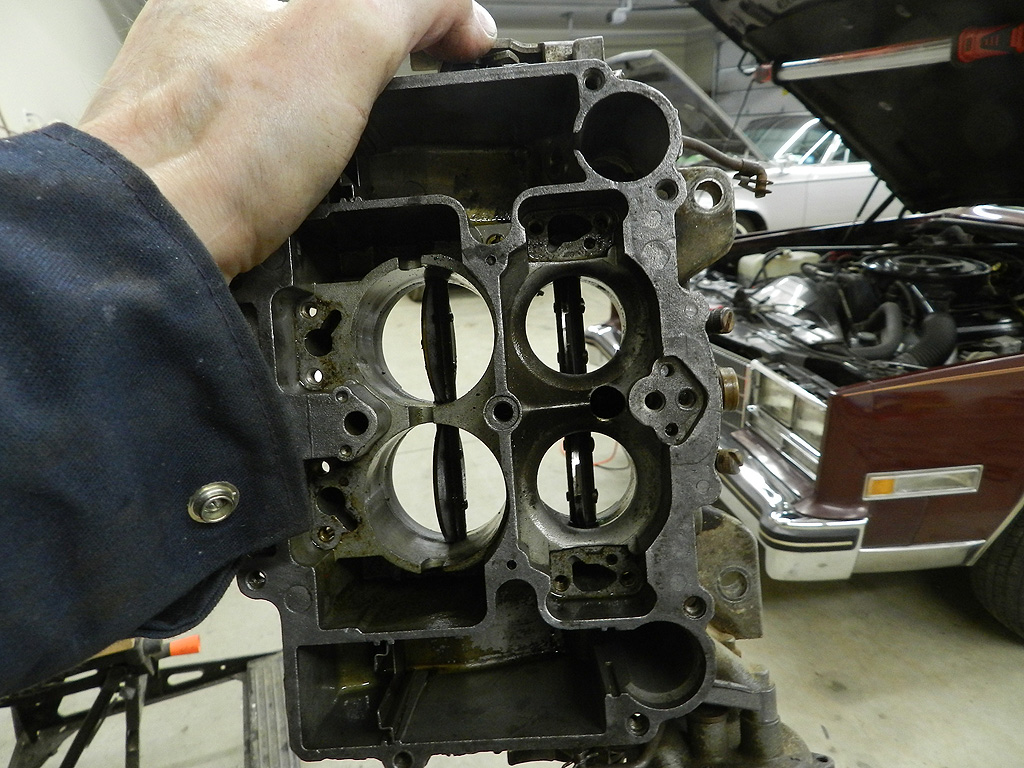

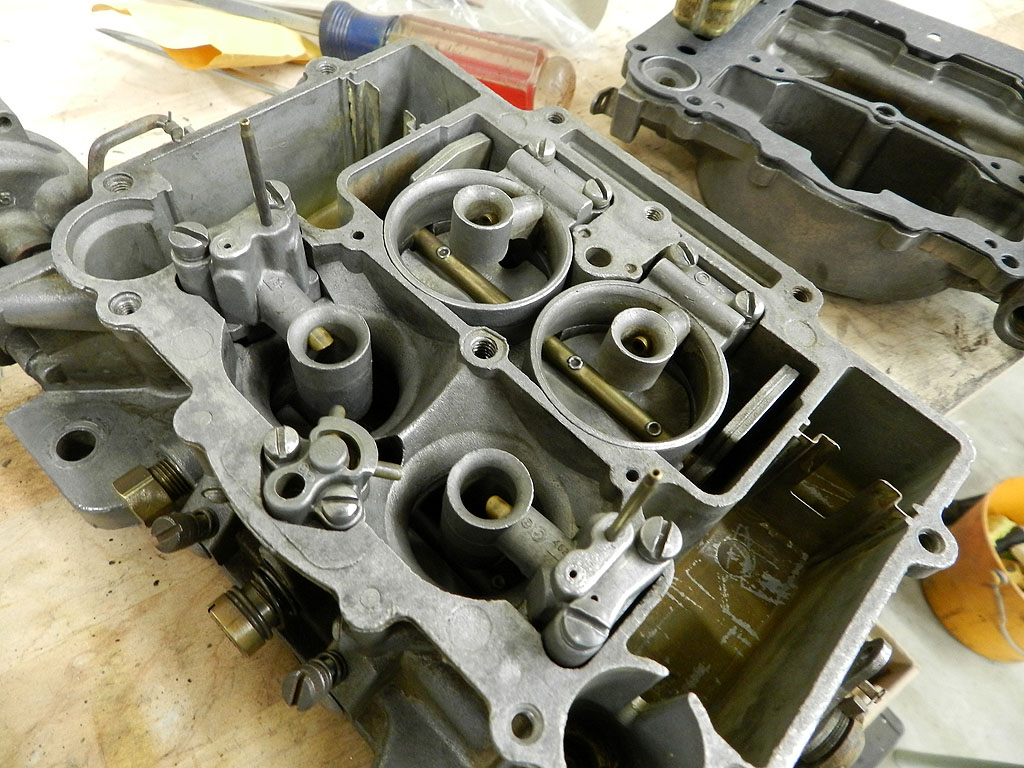

January 1, 2022 in central New York is generally not a 50 degree day, but this year it was. We decided to take advantage of the warm weather and see if we can get the car running. Notes show the last time it ran was 2001 and it ran only briefly off of carburetor prime. Who knows what we will find now? You can click here for that video.

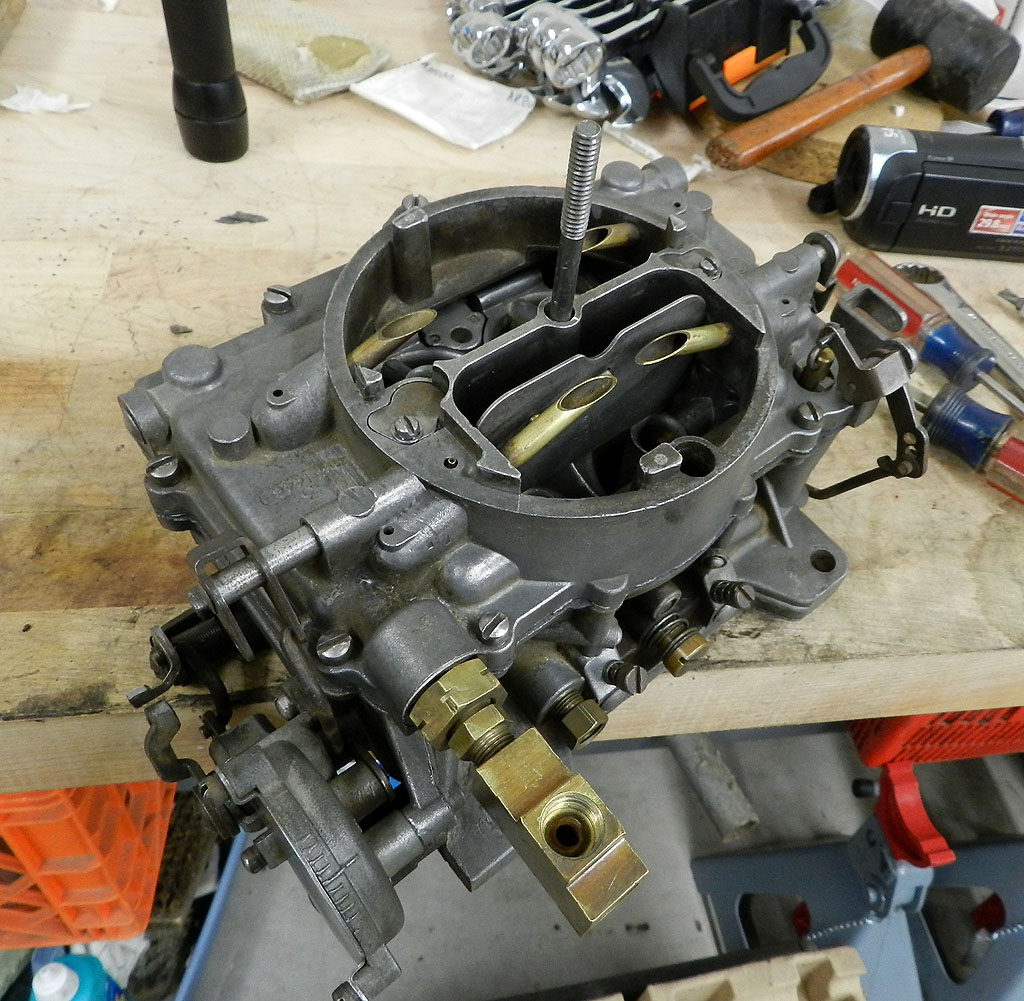

Without much fuss, we got it running. Oil pressure came up, the generator charged, she fired on all 8, but the fuel system will need attention before we can go further. Overall this is good news and good progress.

|